Imagine running a grand orchestra. Each instrument has a role, every note a purpose. But what happens if the violinist lags, or the percussionist rushes ahead? The conductor’s sheet music—the process model—no longer reflects the performance happening on stage. In the realm of business processes, process model repair is like tuning the orchestra back in harmony, ensuring that the actual performance (event data) and the intended score (the model) align once more.

This fascinating intersection of automation, analytics, and process optimization is increasingly vital for modern enterprises. As businesses digitize every transaction, event logs tell a candid story of how things really unfold. Process model repair listens to that story and updates the model—automatically—to reflect reality, not assumption.

1. When the Map Stops Matching the Territory

Every business process starts with a map—a visual representation of how work should flow. But as systems evolve, people improvise, and exceptions pile up, the map drifts away from the territory. What’s drawn in BPMN diagrams no longer matches what’s happening in ERP systems.

Consider a retail company that noticed increasing customer complaints about delayed refunds. Their designed process model claimed refunds were approved within 48 hours. Yet, their event logs painted a different picture: approvals averaged 96 hours. Using automated process model repair techniques, analysts discovered a hidden loop—manual verification steps added by customer support agents to prevent fraud. Instead of manually updating the model, repair algorithms adjusted the workflow diagram to reflect this reality.

The result? A more accurate model that guided process redesign—ultimately reducing refund times and boosting customer satisfaction.

(If you’re exploring a ba analyst course, understanding how such analytical insights emerge from event logs is a critical skill. Process repair is one of those advanced applications that transforms raw data into actionable process intelligence.)

2. The Mechanics of Repair: Listening to the Digital Footprints

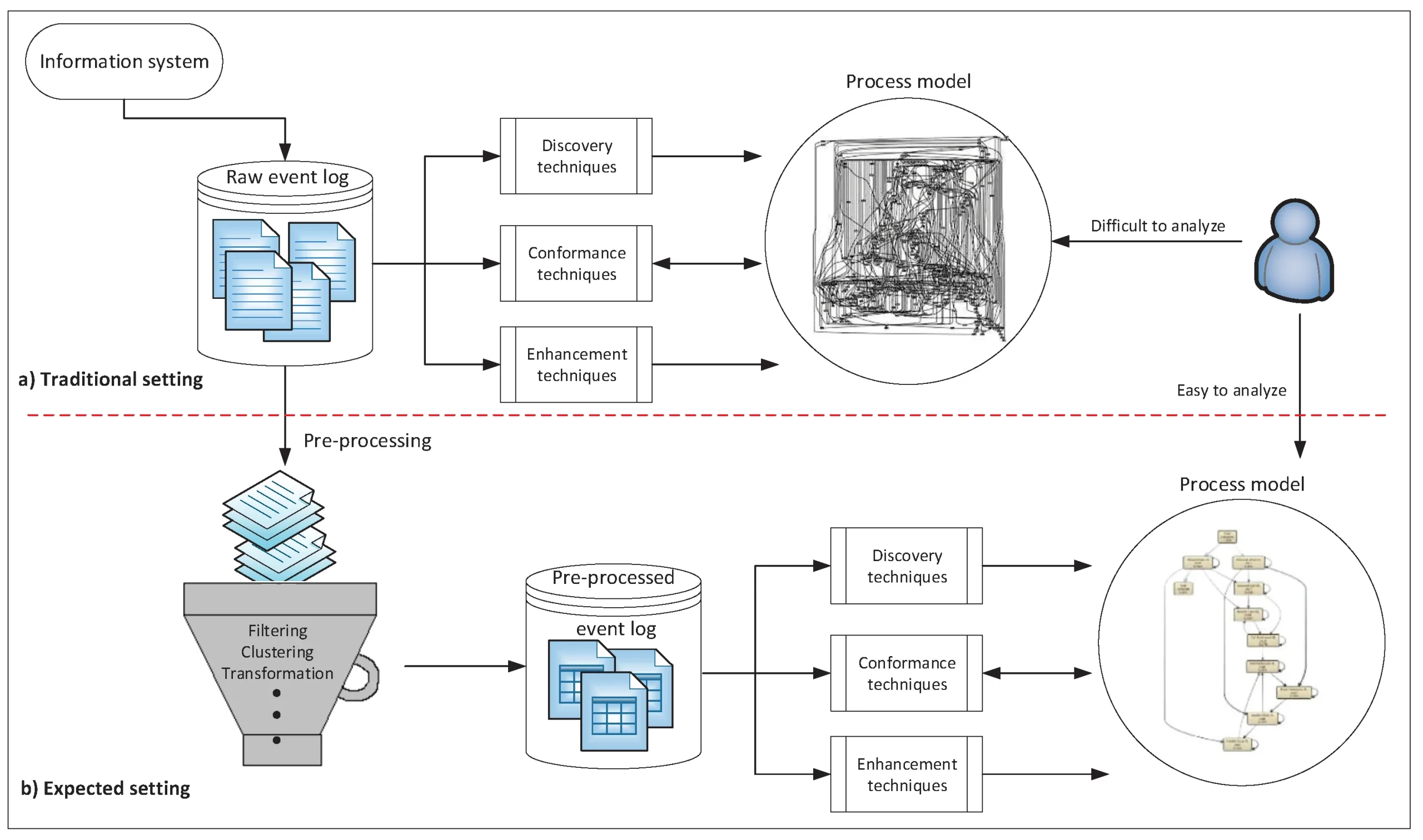

At the heart of process model repair is event data—digital footprints left by every task completion, form submission, and approval click. Automated repair algorithms compare these footprints to the designed model, detect mismatches, and propose minimal, meaningful changes.

Think of it like autocorrect for business workflows. Instead of punishing deviations, it learns from them. Techniques like conformance checking detect where reality diverges from design, and process mining algorithms (such as alignment-based or token-based replay) pinpoint precisely which transitions misbehave.

In many tools, these repairs happen visually: missing branches are added, redundant loops are removed, and time-based deviations become explicit conditions. For organizations running hundreds of processes, this automation prevents countless hours of manual auditing and diagram redrawing.

(Professionals who complete a business analyst course often find this automation eye-opening—what once took days of modeling workshops can now be done algorithmically, guided by data rather than assumptions.)

3. Case Study 1: Healthcare Scheduling Gets a Data-Driven Fix

A large hospital network faced a chronic issue—surgeons complained about double bookings, while patients faced long wait times. The designed scheduling model was neat on paper but chaotic in reality.

By applying process model repair, analysts imported event data from the hospital’s appointment system. The repair algorithm revealed unrecorded rescheduling steps: manual phone confirmations that were never captured in the model but heavily influenced scheduling delays.

Once this missing logic was added automatically to the model, the hospital introduced digital verification checkpoints. The result was a 25% reduction in patient waiting time and smoother resource allocation across departments.

The key insight? Process model repair didn’t invent new rules—it simply unearthed the truth hiding in plain sight.

4. Case Study 2: Financial Services and the Compliance Gap

In a financial services firm, compliance audits frequently found process deviations in loan approvals. Management assumed employees were skipping verification steps. But the repaired model told a different story.

The event data revealed that the core workflow system had outdated automation scripts that skipped certain validations under specific loan categories. Once identified through automated repair, the issue was fixed, saving millions in potential regulatory fines.

Beyond compliance, this case demonstrated how process repair could act as a forensic tool—diagnosing process “diseases” before they become fatal.

5. Case Study 3: Manufacturing’s Hidden Bottleneck

A European automotive manufacturer used process mining to monitor its supply chain. Everything looked fine—until delivery delays began to spike. Automated repair of the logistics process model uncovered a small but critical deviation: operators often manually re-entered supplier codes when barcode scanners failed. This unlogged detour created data mismatches and shipping delays.

Once the repaired model exposed this deviation, the company upgraded its scanning infrastructure and retrained staff. The impact was immediate—delivery accuracy rose by 15%, and unplanned manual rework virtually disappeared.

6. The Future: Self-Healing Processes

The most exciting direction in this field is self-repairing processes. Imagine systems that continuously monitor event data and automatically update workflows—no human intervention needed. Such adaptive systems could detect inefficiencies, learn from user behavior, and optimize themselves in real time.

Incorporating process model repair into business analytics marks a shift from static documentation to living, breathing workflows. Just as musicians tune their instruments mid-performance, organizations can now retune their processes dynamically, guided by data rather than guesswork.

Conclusion: From Blueprints to Living Systems

Process model repair redefines what it means to manage business processes. It moves us from reactive correction to proactive adaptation—where process models evolve alongside the business itself. In a world overflowing with data, it’s not enough to design workflows; we must let them learn.

For anyone pursuing a ba analyst course or a business analysis course, this is where analysis transcends spreadsheets and becomes orchestration—where algorithms and human insight play in sync. The real art lies not just in drawing the process, but in listening to how it plays out, and ensuring the performance never falls out of tune.

Business Name: ExcelR- Data Science, Data Analytics, Business Analyst Course Training Mumbai

Address: Unit no. 302, 03rd Floor, Ashok Premises, Old Nagardas Rd, Nicolas Wadi Rd, Mogra Village, Gundavali Gaothan, Andheri E, Mumbai, Maharashtra 400069, Phone: 09108238354, Email: enquiry@excelr.com.